Mobile Access Tower 305

The Mobile Access Tower 305 is a scaffold that can be used flexibly thanks to its many configuration options. The scaffold is designed for professionals who need maximum flexibility. The platforms have a length of 305 cm. The platform hooks attached to the platforms are asymmetrically placed, allowing multiple platforms to be aligned directly behind each other. Additionally, multiple scaffolds can be connected to create a larger working surface.

The scaffold components are made of aluminum with a wall thickness of 2mm, making them extremely robust. The strong weld seams ensure guaranteed quality. This scaffold can be set up indoors to a maximum working height of 14 meters and outdoors to a maximum working height of 10 meters.

WIXOR scaffolds are for professional use. The Mobile Access Tower 305 meets the EN1004 standards and is TÜV certified.

Specificaties

Height details

Product Details

Ergonomic triangular wing nut

The triangular wing nut is highly ergonomic, designed to provide an excellent grip and ease of use. Its unique triangular shape allows for better torque application, making it easier to tighten and loosen stabilizers. This innovative design ensures that it can be operated comfortably, even with minimal hand strenght.

Work safe with the safety guardrail

The safety guardrail provides essential fall protection when working at height, ensuring a secure and stable workspace. Designed for scaffolding and elevated platforms, it enhances safety by preventing accidental falls. Wixor offers TÜV-certified configurations that include safety guardrails, meeting strict European safety standards. This guarantees reliability and compliance for professional use in construction and maintenance work.

Telescopic stabilizer

The telescopic stabilizer is designed to easily stabilize your scaffold, ensuring it stays secure and steady during use. Its adjustable length allows for quick and effortless adaptation to different ground conditions, providing a stable base with minimal hassle.

700kg Wheel load

The 200mm scaffolding wheel is designed for heavy-duty use, supporting up to 700kg per wheel. It features a protective layer that enhances durability and prevents floor damage. This high-quality wheel ensures smooth mobility and stability, making it an ideal choice for scaffolding in demanding environments.

Yellow clamp triggers

The design of the clamp triggers ensures that distinguishing between horizontal and diagonal braces is very easy. The yellow clamp triggers on the horizontals clearly indicate a horizontal brace, while the diagonal braces are equipped with black and green elements. This color-coded system allows for quick and accurate identification, making your setup process more efficient and straightforward.

Large platform hatch

The large hatch provides easy access to elevated work areas, offering a wide opening for efficient movement of materials and personnel. Designed for durability and convenience, it ensures smooth operation and secure closure. Perfect for scaffolding and construction sites, the large hatch makes your work more efficient and accessible.

Sliding clip trapdoor

The large trapdoor is designed with safety and convenience in mind. Equipped with a robust sliding clip, this trapdoor provides a reliable locking mechanism to ensure the door remain securely in place. Experience the perfect combination of durability and functionality with the trapdoor sliding clip.

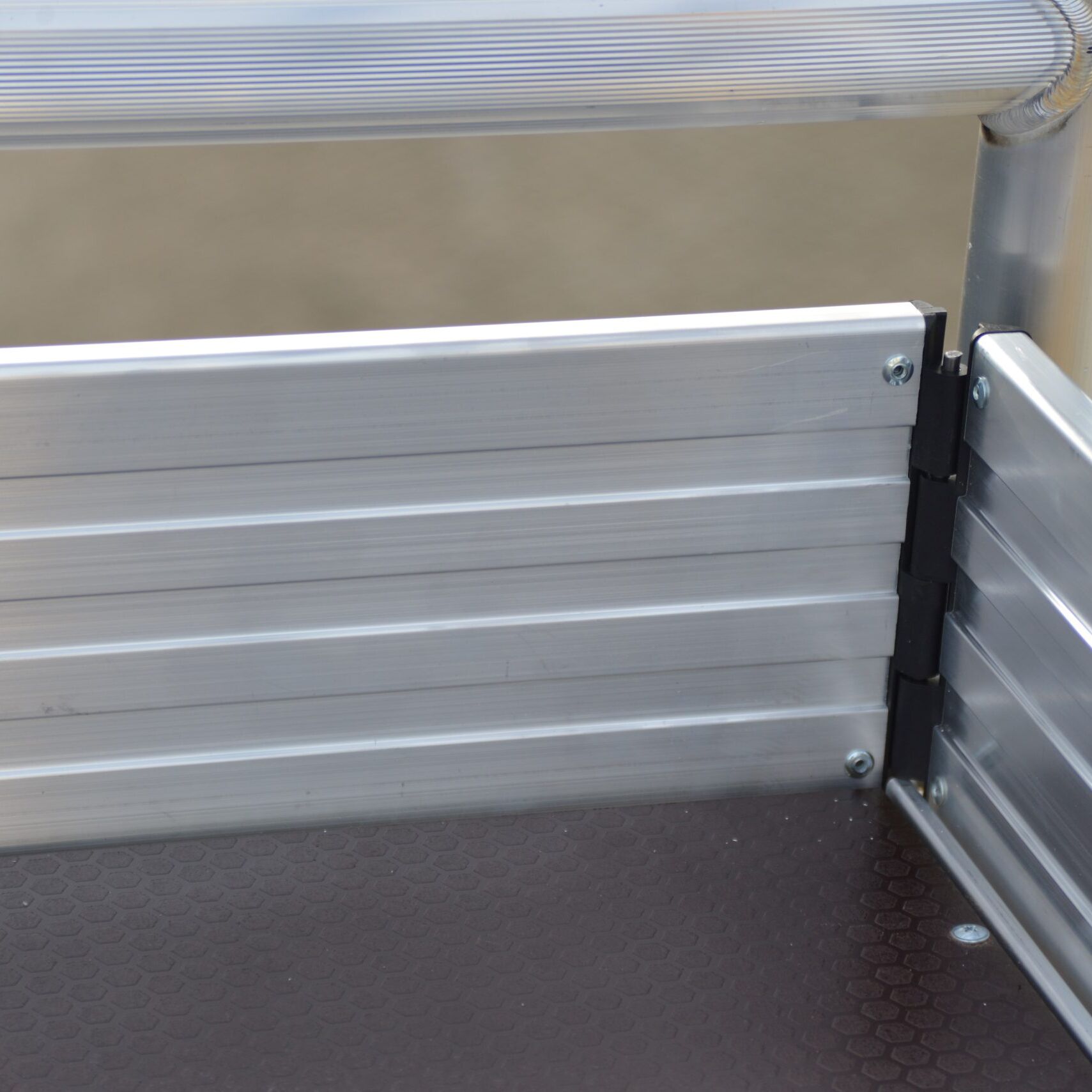

Lightweight aluminium toeboard

The aluminium toeboard is the perfect solution for safety on the job site. Crafted from lightweight alumminium, it provides sturdy protection while remaining easy to handle. The toeboard’s folding feature adds versatility, allowing for compact storage and effortless transportation.

Integrated wind hooks on platforms

The platforms come equipped with integrated wind hooks to ensure maximum safety. On one side, there are two sturdy black hooks, designed to secure the platform firmly in place. The opposite side features a convenient clip, providing an fastening option to keep the platform steady even in windy conditions. The wind protection is a standard feature included with all our platforms. This thoughtful design ensures that our platforms remain reliable and secure, no matter the weather.

Rungs with extra grip

The frames with its anti-slip rungs are designed with safety in mind, offering a reliable grip in any direction. The anti-slip grooves are all around the rungs, providing excellent grip, while accessing the scaffolds.

Weld seam to perfection

The welds on the scaffolds are meticulously crafted to provide durability in every detail. Achieving superior welding is a challenging feat, but is very important to enhance the overall quality of the products. The attention to every detail ensures the creation of top-quality products.

Can't find what you're looking for? Our staff is ready to help you!

Mobile access towers

Mobile towers, also known as mobile access towers or rolling scaffolds, are mobile access towers specially designed for use on construction sites, renovation projects and other situations where safe working at height is essential.

What are mobile access towers?

Mobile access towers are mobile scaffolds, which can be used flexibly thanks to their many configuration options. Wixor’s mobile access towers are designed for professional use. The scaffolds are made of high-quality aluminium, with a wall thickness of 2 mm, making them lightweight and therefore easy to move. The scaffolding’s welded seams ensure guaranteed quality. Mobile access towers provide a stable and safe working surface for work at different heights. There are hooks on the sides of the platforms which are attached asymmetrically, allowing multiple platforms to be placed directly in line with each other. multiple scaffolds can also be coupled together, creating a larger working surface. Mobile towers can be erected indoors to a maximum working height of 14 metres and outdoors to a maximum working height of 10 metres.

One of the biggest advantages of mobile access towers is their mobility. Thanks to the wheels, they can be easily moved from one place to another. The flexibility of the mobile access towers makes them suitable for a wide range of applications, from painting and maintenance to construction work. Rolling towers are also designed with safety in mind and offer a stable working surface with ample space. The scaffold platforms are fitted with anti-slip material. Front railings and edge boards are also provided to prevent fall hazards. Moreover, the mobile towers comply with EN1004 standards and are TÜV certified.

Mobile access towers are relatively easy to assemble and dismantle. Wixor’s scaffolds can be assembled without additional tools. Thanks to their properties, mobile access towers are robust.

Applications of mobile scaffolding

Mobile access towers are indispensable in various sectors. In the construction industry, mobile access towers are frequently used for various jobs, such as bricklaying, painting, and roof repairs. These scaffolds provide a safe and stable workplace for workers and make it possible to work at different heights. Wixor’s mobile scaffolds are suitable for both indoor and outdoor work. However, the maximum working height must be taken into account. Indoors, this is a maximum working height of 10 metres and outdoors, a maximum working height of 14 metres. Mobile towers are also an indispensable tool for maintenance work on buildings and infrastructure. They make it possible to work on, for example, facades, windows and lighting. Mobile access towers are also used in the event industry for erecting stages, lighting and decorations. The mobility of scaffolding makes it easy to make quick adjustments during the construction phase.

A variety of mobile access towers are available, each with their own specific uses and advantages. Narrow access towers are ideal for use in tight spaces and indoors. These scaffolds are compact and easy to manoeuvre, making them perfect for work in corridors, stairwells and other confined spaces. Wide mobile access towers offer more working space and stability, making them suitable for larger projects. These mobile access towers have a wider longer platform, offering more room to work.

Assembling mobile scaffolding

When assembling a mobile scaffold, the first thing to do is to look for a workplace with a stable and level surface. Next, you can start building the base of the scaffold. You start with the frames, under which you mount the wheels. Next, you can place a platform between the frames and attach the braces, which provide strength to the mobile scaffold. You repeat these steps until you reach the top, at the desired working height. It is important to fit the work platform with safety guardrails and toeboards. This will prevent materials or tools from falling off the platform.

Maintenance and inspections

Regular maintenance and inspection of scaffolding is important. By cleaning the scaffold after use, moving parts are less likely to be damaged or jammed. It is important to inspect all parts, such as wheels, braces and platforms, for wear, rust or other damage. Worn or damaged parts should be replaced to avoid accidents.

Purchasing a mobile scaffold

When choosing a mobile access tower, it is important to consider several factors. Firstly, the maximum working height required for a specific project should be considered. This should also take into account the legal maximum working height for indoors and outdoors. Care should be taken to ensure that the scaffolding is high enough for the work to be carried out. Secondly, the maximum load capacity of the scaffold should be checked to ensure that it is suitable for the expected load. Take the weight of workers into account. The load capacity is usually 750kg. Finally, it is important to look at the material of the mobile scaffold tower and the necessary accessories. Wixor mobile access towers are made of high-quality aluminium, which is also rustproof. The scaffolds should have safety guardrails, guardrail frames, toeboards and platforms. While price is an important factor when buying a rolling scaffold, it is also very important to pay attention to quality and safety.

Conclusion

Mobile access towers, also known as scaffolding or rolling scaffold, are essential tools for working safely and efficiently at height. These scaffolds offer numerous advantages, including mobility, flexibility and safety. Choosing the right rolling scaffold and purchasing the necessary safety equipment to go with it makes it easy to carry out work at height. Wixor’s mobile access towers are made for professional use and comply with EN1004 standards, as well as being TÜV certified. In short, the rolling scaffold is the ideal tool for working at height in various sectors, including the construction industry.